Remotely monitoring elevators with IoT technology

Fujitec remotely monitors elevators with innovative IoT technology

ABOUT

Evolution of the elevator maintenance work with the site!

Fujitec CO., LTD (henceforth known as Fujitec) is a specialized manufacturer that provides elevator and escalator installation, maintenance, research and development, and operations. This Japanese business develops elevators and escalators that are used in hotels, offices, condominiums and more across Japan and abroad.

Elevators and escalators are machinery that must be safe to ride and operate, which is why regular maintenance is mandatory by law. For many years, elevator and escalator maintenance has been done on-site, however, Fujitec wanted to change how elevator and escalator maintenance is performed using IoT technology.

CHALLENGE

Desire for remote elevator and escalator monitoring

Fujitec found that there was always a desire for remote elevator and escalator monitoring.

Researching similar cases of IoT maintenance applications, they discovered that many overseas IoT projects used cellular connectivity to successfully monitor elevators remotely.

However, cellular connectivity requires a contract for each country at use. This was problematic for Fujitec, as they had customers around the world.

SOLUTION

After some deliberation, Fujitec realized that they could deliver remote elevator and escalator monitoring and maintenance to their overseas customers by incorporating the cellular connectivity while the equipment was being created.

Fujitech quickly realized that an IoT system can’t be completed with just a server and application like any ordinary business system.

It needed extensive information about each IoT-connected device as well, along with connectivity that worked for their specific project.

This is when they discovered Soracom and began working on a concrete IoT system.

WHY SORACOM

Preventive analysis by analyzing operational data and quickly responding when failures occur

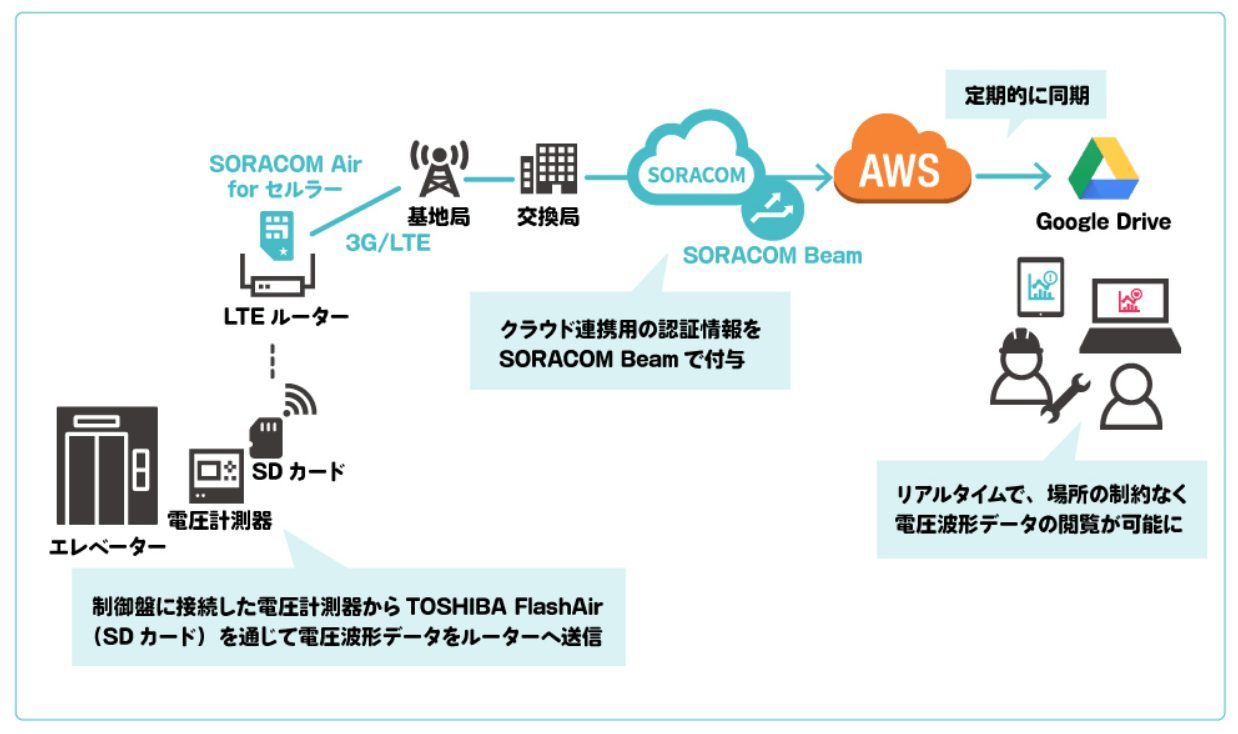

Fujitec started to monitor the humidity and temperature of their elevators. This consisted of a straightforward system with IoT sensors that collected data on temperature and humidity, and relayed the information to Amazon Web Services using Soracom cellular connectivity.

Since Fujitec decided to power their IoT project with Soracom cellular connectivity, they didn’t have to lay down a network or prepare a server, allowing them to complete their prototype in about two weeks.

After the success of their prototype, Fujitec decided to develop a method to provide remote monitoring services for overseas customers. Today, Fujitec can remotely view the elevator operation stats for overseas customers, helping to provide preventive analysis by analyzing operational data and quickly responding when failures occur.

By using SORACOM Air SIM cards for each IoT sensor, Fujitec was able to immediately launch their IoT system with cellular connectivity.

SYSTEM CONFIGURATION

FUTURE DEVELOPMENTS

Fujitec believes that there are three cases where the manufacturing industry could benefit from IoT technology.

- When data acquisition and data analysis are physically separate from one another. An example of this could be seen within global projects as well as systems that cover a wide geographic range.

- Where acquiring data doesn’t have to wait on data analysis. Being able to collect data automatically without needing manual permission shortens the time required for analysis.

- When a system is acquiring data from devices that aren’t connected to the internet. For instance, an individual elevator or escalator can have data gathered from it for maintenance purposes, but it isn’t necessarily connected to the internet. Collecting data on predictive analysis using IoT, AI and machine learning provides customers with more security, convenience and added value.

Fujitec finds the best way to incorporate IoT technology into the manufacturing industry is to start experimenting with it. Even if the first attempts are weak, the practice will help businesses create meaningful solutions in the long term. In addition, they recommend interacting with cloud technology, and finding a knowledgeable partner like Soracom to help build a productive IoT system.