EXACT Technology

Making concrete stronger, safer, and more sustainable

The Opportunity

Stronger, greener, more durable infrastructure

After water, concrete may well be the most widely used substance on earth. Its history in construction goes back over 10,000 years and includes structures that amaze and inspire today, from Rome’s Pantheon to Nevada’s Hoover Dam. Concrete serves as the foundation for nearly every human endeavor, from housing and energy production to transportation, health care, manufacturing, and disaster prevention.

But concrete production also represents one of the world’s largest single sources of carbon emissions. As the world moves toward greater carbon neutrality, builders are seeking opportunities to make construction projects more efficient. One simple but effective approach is to increase structural durability, minimizing the need for future remediation and replacement.

Enter EXACT Technology, a Toronto based startup that creates data-driven solutions for precast, infrastructure, and high-rise construction. Constructors of all types and sizes use monitoring data from EXACT’s hardware and software to build their projects faster, safer and more sustainably.

“In Toronto and across North America, there are a lot of crumbling structures that were built in the ‘40s, ‘50s, and ‘60s,” explains Jordan Korenzvit, CEO and co-founder of EXACT. “It’s costing a lot of money to remediate these issues — and it’s also extremely dangerous when concrete chunks fall onto people and cars.”

This is not a hypothetical concern. In 2019, one of the three bridges that ring the San Francisco Bay had to be shut down for emergency repairs when concrete began to separate and drop onto vehicles traversing the lower roadway. Fortunately no drivers were injured, but the unscheduled closure and emergency repair caused gridlock across the region for days.

Fortunately, science has caught up. As Korenzvit observes, “Engineers know if you monitor that concrete while it’s being placed for the first seven days, and you keep the temperature of that concrete within certain constraints, you will get 125 years of a lifespan out of your bridge, dam, building, tunnel, or whatever the project is.”

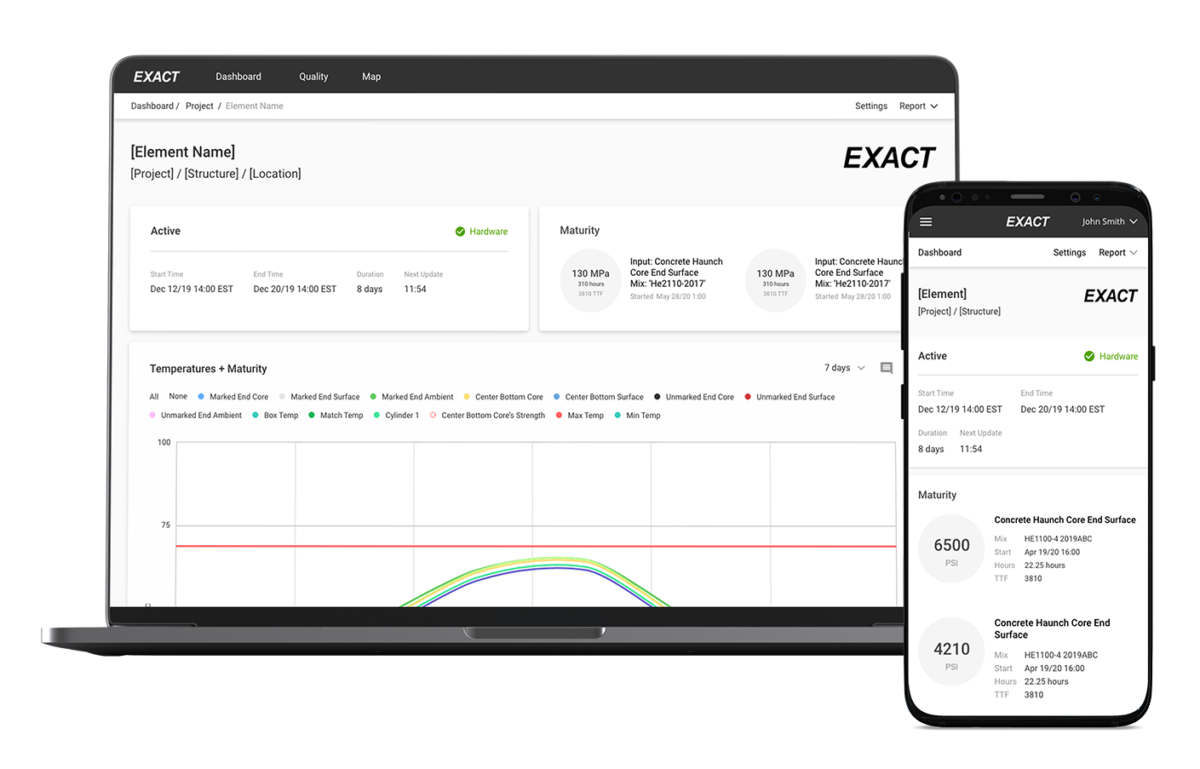

EXACT Technology delivers the 21st century hardware and software that lets structural engineers and contractors monitor the curing process in real time to ensure their projects meet those specifications and last a lifetime.

CEO and Co-Founder, EXACT Technology“The connectivity is sorted out. Our customers just plug it in. And Soracom only charges us when they use the service.”

The Solution

Concrete insight for a perfect cure

As with many stories of innovation, the idea for EXACT Technology unfolded over a dinner conversation between friends.

“Four years ago, a friend (Stacia van Zetten, now co-founder and chief strategy officer at EXACT), and I were discussing her then current project,” explains Korenzvit. “At the time, she was responsible for a new subway system being built in Toronto consisting of 25 stations. It was a several-billion dollar project involving lots of concrete. There wasn’t an efficient way to make sure that the concrete was going to perform.”

Van Zetten and her team were using loggers designed in the eighties with green LCD screens and thermocouple wire going into every wall, slab, roof, and piece of mass concrete. In total, there were 1,200 pores that needed monitoring with 9 temperature points per pore.

“It was an impossible objective,” says Korenzvit. “Equipment was unreliable, and someone would need to drive to every construction site each morning with a clipboard to write down the temperatures on the screen — and then go back in the afternoon to every site and write down the temperatures. The teams would then receive the data to analyze over email.”

At the time, Korenzvit was working on projects related to custom home automation with automatic integrations. With this knowledge, he decided to build a simple prototype which took him a few days to create. They tested it on one of the subway stations.

“We installed it and it worked,” says Korenzvit. “For the first time ever, the team had real-time online data, refreshed every 15 minutes. We took this experiment to a decision maker for the project and opened up a purchase order a few months later.”

From that first customer engagement, EXACT has grown to become a leading solution for real-time concrete monitoring. Today, EXACT Technology monitors over $20B in public and private construction projects. Customers rely on EXACT for continuous insight into critical parameters, with automatic alerts, so builders can take action and fix issues before they turn into expensive problems. And construction projects can can begin using EXACT without committing to expensive IT investments.

WHY SORACOM

Reliability, integrity, scalability

Industrial customers require industrial-grade reliability. For EXACT Technology, getting connectivity right was mission-critical, but it wasn’t always easy.

“We worked with several carriers at the beginning, but none of them were able to deliver what we needed,” says Korenzvit. “One company went bankrupt and their SIMs were shut down overnight without notice. We needed to recall the 100 devices that we had out in the field. It was scary. So I sought out stronger partners with bigger, better companies with strong reputations.”

“Looking at other enterprise partners, we would have needed to sign multi-year contracts at several hundred thousand dollars or more just to get proper technical support and multicarrier service. But how do you sign a multi-year deal with companies like theirs that are constantly changing?

‘We heard that Soracom was a Japanese company built on AWS as the technical core, with a reliable, worldwide, multicarrier service. Being able to hop between networks with just one SIM card was key.”

Beyond offering a reliable, high-integrity solution for connectivity, Soracom also gives EXACT end-to-end control over network security.

“There’s obviously a lot of concerns about security nowadays with networks — that we’re somehow going to open up a backdoor unintentionally or that we’ll need an extensive audit from the IT departments at a larger company. With Soracom, we can say from the beginning that we control data communication from beginning to end. It’s our responsibility and turnkey with our own relays, portal, and loggers. Our clients just need a web browser to get online. We don’t touch our carriers’ existing infrastructure.”

EXACT is able to ship its monitoring solution all over the world with a Soracom SIM card.

“The connectivity is sorted out,” says Korenzvit. “Our customers just plug it in. And Soracom only charges us when they use the service. It’s exactly the way that we charge our clients.”

The Outcome

Helping builders reduce costs and improve outcomes worldwide

EXACT Technology has expanded and scaled to reach a global customer base, particularly across North America and Australia. Fueling this growth was a partnership and acquisition in early 2021 — EXACT acquired Products Engineering, Inc., which has more than 50+ years of experience with precast technology and has worked with practically every precaster in the United States.

“It took them decades to build these relationships that would not be possible to replicate,” says Korenzvit. “As we get deeper into the American market, connectivity is key. We need to be present on certain networks, especially in rural areas where cellular access is sparse.”

“We haven’t focused on international expansion yet, but it’s happening organically.”