Researchers Enable Real-Time Remote Control of Smart Factory Between South Korea and Finland

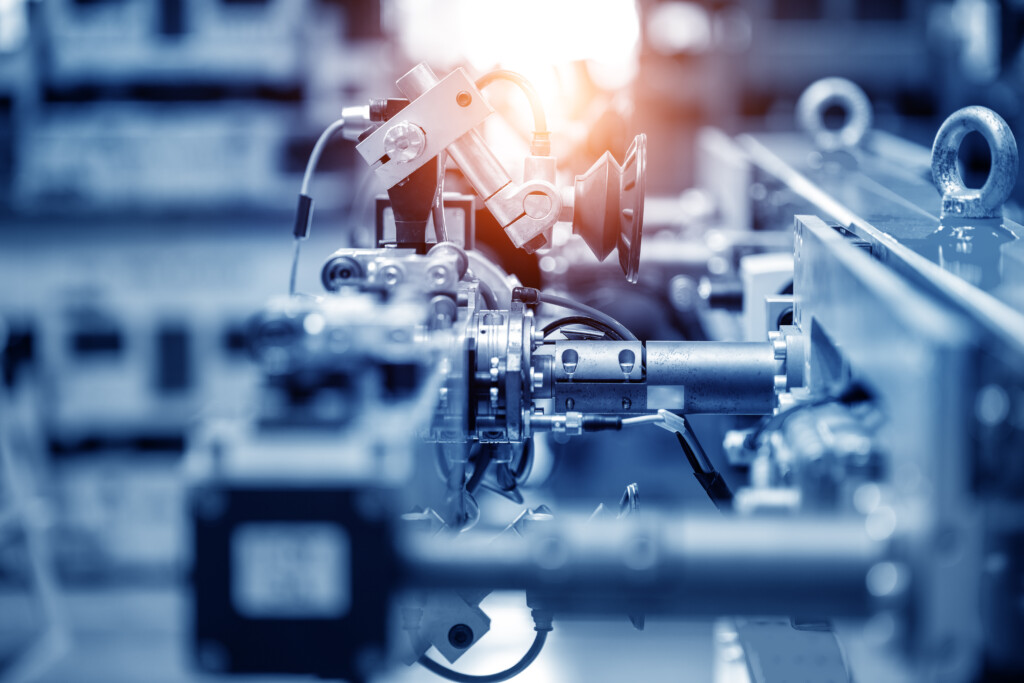

A new technology developed by the Korean government-funded Electronics and Telecommunications Research Institute (ETRI) has established real-time remote control of a smart factory from thousands of kilometers away.

Using a combination of ultra-low latency 5G cellular connectivity and an intercontinental wired network, the ETRI successfully connected a smart factory in the Korea Institute of Industrial Technology in Hayang-eup, Gyeongsan-si, Gyeongsangbuk-do, to Oulu University in Finland, roughly 7,000 kilometers away.

Using this connectivity, researchers were able to remotely operate machinery in an industrial center run primarily by robots and automation rather than human employees. With the global smart factory market expected to reach a valuation of USD $514.29 Billion by 2027, being able to remotely control a facility’s operations from so far away has any number of applications for the IIoT.

Before we can discuss them, however, let’s look at how this was achieved.

How Did this Smart Factory Connection Work?

To enable this kind of long-distance connection, both the factory in Gyeongsan and ETRI Control Center in Oulu utilized dedicated 5G networks endemic to each location. Oulu university employed a private test network, while the Gyeongsan operation worked off of the Korean domestic test network, KOREN.

In The Gyeongsan facility, ETRI deployed a remote manufacturing execution system, which allows for real-time facility control and status monitoring through the remote Supervisory Control and Data Acquisition control panel. This allowed for the remote control and status monitoring of manufacturing robots at the Oulu control center, with users able to remotely guide manufacturing processes and observe their effects using atmospheric and other data sensors.

All of this was accomplished with less than .01 seconds of delay in the Korean facility, and less than .3 seconds of delay in the Finnish locale.

The goal of this test was to help introduce a new remote manufacturing diversification service that improves the service scope and availability of smart factories – particularly in remote and inhospitable areas.

The Next Wave of IIoT Solutions

Of course, this is only one solution being put forth to help revitalize the global manufacturing industry. A bevy of technological developments are ushering in the next wave of IIoT solutions – and cellular connectivity is a key facet of the collaborative technologies that are being deployed in smart Factories.

Some technologies being used to make manufacturing more efficient include:

- Digital Twin – by creating virtual models of a factory, machine, or product, users can better test and optimize their assets, test out new workflows, or even revise products to improve functionality in a risk-free environment.

- Machine-Learning-Based-Visual Inspection – Remove the human element from simple monitoring and inspection tasks by utilizing high-res cameras and machine learning algorithms to perform these menial tasks.

- Autonomous Mobile Robots – Utilizing Complex AI, these robots can work independently of human operators to perform mission-critical tasks, maintenance, or simply automate production on the factory floor.

These solutions, and more, are helping usher in a more streamlined manufacturing sector.

Security Is Essential in a Smart Factory

Of course, any smart factory that connects to the internet – particularly one reliant on remote guidance of machinery and procedures – will want to put cybersecurity at the forefront. Manufacturing is one of the most commonly targeted industries for hackers, with malware attacks in particular devastating several organizations in recent years.

There are many common-sense solutions that the designers of IIoT solutions can employ in order to improve their security efforts. For one, making sure that every device within the factory is up-to-date on all software updates and security patches eliminates one of the most common risk factors for IoT devices.

Designers can go one step further by architecting their solution to avoid the public internet. By utilizing private networks to avoid public IP addresses, architects eliminate the easiest entry point for bad actors looking to steal data or compromise a smart factory.

Cyber security training for any staff that may interact with connected devices within the factory – remotely or otherwise – can also tighten up security efforts considerably.

The Future is Now

The ETRI demonstration represents a milestone in the feasibility of remotely operating, monitoring, and maintaining complex machinery and smart factories from another country altogether. This opens up a number of opportunities for multinational organizations to launch manufacturing operations in remote locations -even across international lines – without the staffing concerns that can come with such an endeavor.

And researchers aren’t done yet, as they have announced plans to implement hyperspatial services for a more integral understanding of the remote environment. ETRI has also cast its eyes further forward, hoping to design future factories utilizing the 6G network being pioneered at the University of Oulu.

………………

Got a question for Soracom? Whether you’re an existing customer, interested in learning more about our product and services, or want to learn about our Partner program – we’d love to hear from you!