How AI and IoT Power Preventative Maintenance

As artificial intelligence (AI) continues to evolve, its ability to process data faster than a human operator made it an essential part of modern industry faster than anyone predicted. When combined with IoT sensors and the right connectivity technologies, industrial facilities, factories, and myriad other use cases utilize AI to help perform preventive maintenance on essential equipment.

Running equipment until it breaks down is 3-10 times more expensive than regular maintenance, and with the average cost of unplanned downtime hovering around $260K per hour (and the average equipment outage lasting 4 hours or $1.04 million), keeping your deployment serviced before an outage is more important than ever. And as early adopters have shown, the most effective maintenance programs involve smart devices, smart connectivity, and AI.

The Importance of IoT Sensors to Preventative Maintenance

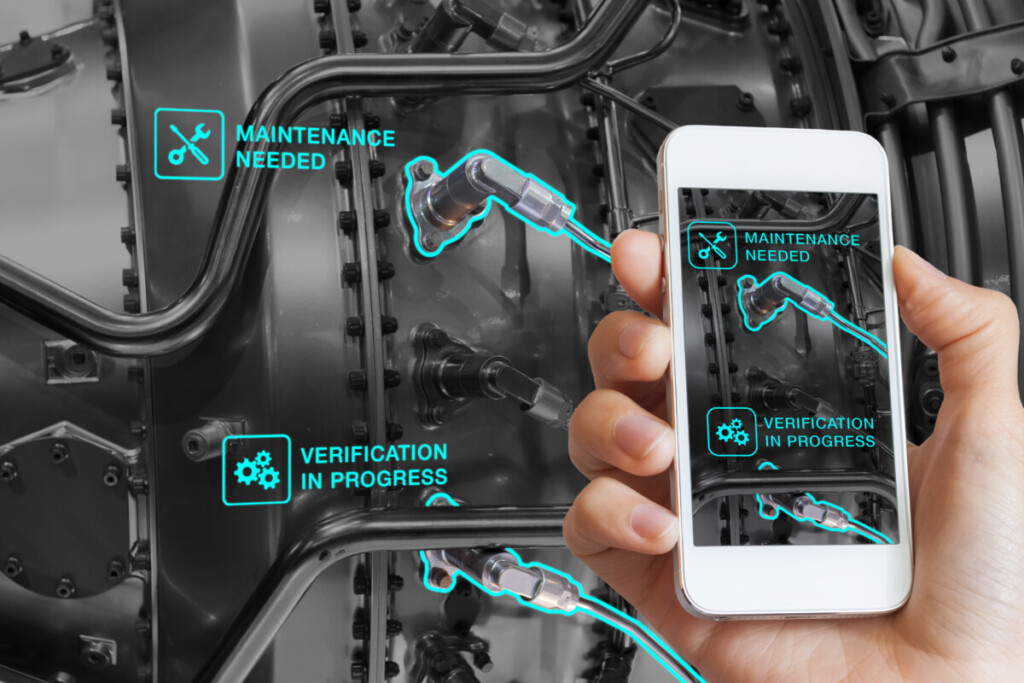

As we have discussed in the past, IoT sensors are the driving force behind predictive maintenance, providing the data necessary to anticipate and prevent costly production errors and work stoppages. They do so by measuring the conditions of equipment and the atmosphere, comparing it to the baseline for the area/machinery, and making notes of variations from optimal status. Deviations may be captured, analyzed, and then turned into timely preventive maintenance savings and an end to traditional “milk run” maintenance that creates downtime when line work is not needed.

There are many types of IoT sensors available to create the right mix for your maintenance.

The most popular and proven include:

- Temperature Sensors: These are valuable to monitor a device’s performance, as peaks in temperature can indicate wear and tear on a device or any potential fire hazard

- Humidity Sensors: High levels of humidity can be indicative of leaks or can lead to a buildup of corrosive rust or mold

- Vibration Sensors: Excessive motion in your equipment can be a sign of loose casings, improperly installed racks, or imminent breakdown

- Smart Buttons: Easy automation tools help maintain baseline settings for equipment and processes and can help hasten response to potential breakdowns

Utilizing these tools to keep tabs on your device performance can help floor managers stay ahead of any equipment failures, slowdowns, and costly downtime, and with powerful gateways to support this infrastructure throughout any type of industrial facility or factory, such as those from Multitech these processes can become an integral part of operational optimization in a matter of weeks.

We’ve supported IoT devices used to maintain factories and industrial facilities/equipment for years.

Some of our favorite use cases include:

- Charge Analytics – Monitors air quality and processes for safety, compliance, and efficiency

- Telesense – Utilizes monitoring sensors and predictive algorithms to maintain commercial grain facilities

- Toku Systems – Monitors industrial vats, wells, and tanks with pressure sensors to provide insight into the condition and health of those assets

The Role of Smart IoT Connectivity in Your Preventative Maintenance

Of course, your devices won’t get very far without proper connectivity. Smart IoT connectivity is essential for secure and reliable connections, linking equipment and data to your own servers or the cloud in a more secure and reliable fashion than in more public settings.

While using even standard IoT connectivity in a factory or industrial setting can enable essential processes like real-time monitoring and analytics, smart connectivity offers more than a mere portal to the internet. Smart connectivity goes a step beyond offloading much of a network’s communication overhead to its connectivity provider. These processes can include:

- Authentication

- Cloud Integration

- Data Encryption

- Remote Provisioning

Smart connectivity from providers like Soracom can also enhance security through value-added services that can keep your data from the public internet or create virtual private networks to control who can and cannot access your data. Beyond that, smart connectivity providers will offer industrial-grade SIM cards that are heartier and more resilient than the average card, providing a further layer of physical security for devices.

Of course, a smart connectivity provider will also offer a bevy of connectivity technology options. This can include everything from basic cellular connectivity to global satellite coverage to lower power (and lower cost) options like LoRaWan.

All of this adds up to a more efficient, resilient, and cost-effective IoT deployment – something every factory or industrial facility should be interested in.

The Impact of Artificial Intelligence on Preventative Maintenance

To maximize the efficiency of your predictive maintenance efforts, AI can be a game changer. Modern artificial intelligence boasts a speed of inference of about 1.5 seconds, and unlike a human operator, it doesn’t require rest or breaks from performing an intended task. This means that an AI system can provide near-instant assessments of equipment status, floor safety, or overall factory performance, even during automated hours of operation with no human staff present.

Suitably advanced AI solutions, like AI Dynamics’ suite of products, can go one step further, learning to anticipate issues like equipment failure before they happen. With enough accumulated data, AI systems can notice the smallest variation in the integrity of an operation and signal to floor managers or maintenance personnel that a piece will need to be fixed or replaced. Modern AI solutions can process numerical, textual, and even visual data for deep-learning functionality, helping to not only improve efficiency but also reduce operational costs.

A McKinsey report posts that Predictive Maintenance is the most valuable use of AI in manufacturing and industrial settings, though it’s far from the only application of AI within factory and industrial facilities. From product development and warehouse management to automation and quality control, AI looks to be a fixture in the manufacturing and industrial spaces in the years to come.

Conclusion

In short, preventative maintenance is expected to grow in importance and relevance in the coming years, with MarketsandMarkets predicting that the market for predictive maintenance could reach a valuation of $15.9 billion by 2026. That growth will largely be driven by investments in smart sensors and accompanying hardware, though continued investment in AI solutions and the smart connectivity that powers them will only increase over that time frame as well.

When combined, these solutions can create a more efficient, cost-conscious, and reliable IoT infrastructure that supports near-constant uptime. If you are just starting your journey into preventative maintenance, you can find everything you need to build your own solution at Mouser. Learn more here.

………………

Got any questions about an IoT deployment? Soracom offers a number of powerful solutions that have made us a visionary in the IoT space. Chat with us today to learn how a partnership with Soracom can get your project up and running easily and securely. Contact us today!